Understanding HVAC Lifecycles: When to Repair vs. When to Replace

Commercial HVAC systems are a major investment, and building owners often face a critical decision: repair the existing system or invest in a full replacement? While repairs can extend the life of your equipment, there comes a point where replacing the unit is the smarter financial and operational choice. In this post, we’ll break down key factors that determine when to repair and when to replace your HVAC system.

1. The Typical HVAC Lifecycle

Most commercial HVAC systems last 15-25 years, depending on maintenance, usage, and environmental factors. Some of these are driven primarily by Here’s a general breakdown of common equipment lifespans:

| System | Expected Lifespan |

|---|---|

| Rooftop Unit (RTU) | 15-20 years |

| Air Handlers | 20-30 years |

| Heat Pumps | 15-20 years |

| Split Systems | 15-20 years |

| Chillers | 20-25 years |

| Cooling Towers | 20-30 years |

| Boilers | 20-30 years |

| Base-Mounted Pumps | 20-30 years |

| Pipe -Mounted Pumps | 10-15 years |

| Terminal Units | 20-25 years |

| Metal Ductwork | 40-60 years |

| Flexible Ductwork | 15-30 years |

While these are general guidelines, efficiency, maintenance costs, and technological advancements play a role in deciding when to upgrade.

With that being said, systems and components can age differently. We call the two aging mechanisms cycle aging and calendar aging.

| Component | Primary Aging Mechanism | Notes |

|---|---|---|

| Compressors | Cycle Aging | Frequent start-stop cycles, load fluctuations, and refrigerant pressure changes cause wear. Hard starts and short cycling accelerate failure. |

| Fans & Blowers | Cycle Aging | Bearings and motors degrade over time due to constant operation, but calendar aging can also occur due to dust accumulation and corrosion. |

| Coils (Evaporator, Condenser, Heating) | Calendar Aging | Corrosion, fouling, and refrigerant leaks occur over time, reducing efficiency. Corrosion-resistant coatings can extend lifespan. |

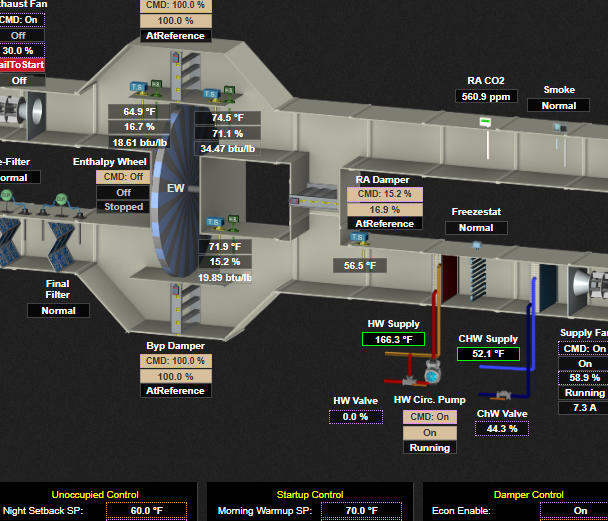

| Building Automation System (BAS) Controllers | Calendar Aging | Aging occurs due to outdated software, component degradation, and communication failures. |

| Cooling Towers | Both | Fans and pumps experience cycle aging; structural materials (metal, fiberglass), and fill material degrade due to calendar aging from water exposure, scaling, and biological growth. |

2. Key Signs It’s Time to Repair

If your HVAC system is experiencing issues but is still within its expected lifespan, repairs may be the best choice. Consider repairing if:

✅

The issue is minor (e.g., a faulty sensor, valve replacement, or refrigerant leak)

✅

Repair costs are less than 30% of the cost of a new system

✅

Your energy bills are stable and reasonable

✅

The unit is under 15 years old

✅

The problem is due to lack of maintenance (e.g., clogged filters, dirty coils)

Example Scenario:

An

8-year-old packaged rooftop unit is struggling due to a failing compressor. If replacing the compressor is significantly cheaper than a new unit, and the system still meets the building’s needs,

repairing makes sense.

3. When It’s Time to Replace

Sometimes, repairing is just delaying the inevitable—and costing you more in the long run. You should consider replacing your system if:

🚨

The unit's age is within 80% of its expected lifespan, greater

🚨

Repairs exceed 50% of the replacement cost

🚨

Your energy bills are rising despite no major operational changes

🚨

The system uses outdated refrigerants (like R-22, which is now phased out and can be cost-prohibitive to procure)

🚨

The unit struggles to maintain temperature or humidity levels

Example Scenario:

A

22-year-old chiller has had multiple breakdowns, and a recent failure requires a $30,000 repair. A new, energy-efficient chiller would reduce operating costs significantly and qualify for utility rebates.

Replacing the unit is the smarter financial choice.

4. Cost Analysis: Repair vs. Replacement

A good rule of thumb: if the cost of a major repair exceeds 50% of the cost of a new unit, replacement is the better option.

Let’s break down this example of R-22 rooftop unit from the 2000's:

| Option | Cost | Remaining Life | Annual Energy Cost | Total 5 Year Cost |

|---|---|---|---|---|

| Repair RTU | $12,000 | 5 years | $7,200 | $48,000 |

| Replace RTU | $20,000 | 20 years | $5,000 | $45,000 |

In this case, the replacement provides a longer service life, better energy efficiency, and pays for itself within five years.

5. Benefits of Upgrading Your HVAC System

If a replacement is needed, the benefits go beyond just avoiding repair costs:

✔️

Lower Energy Bills – Newer units are often 20-40% more efficient, thanks to variable speed fans, compressors, and new refrigerant developments

✔️

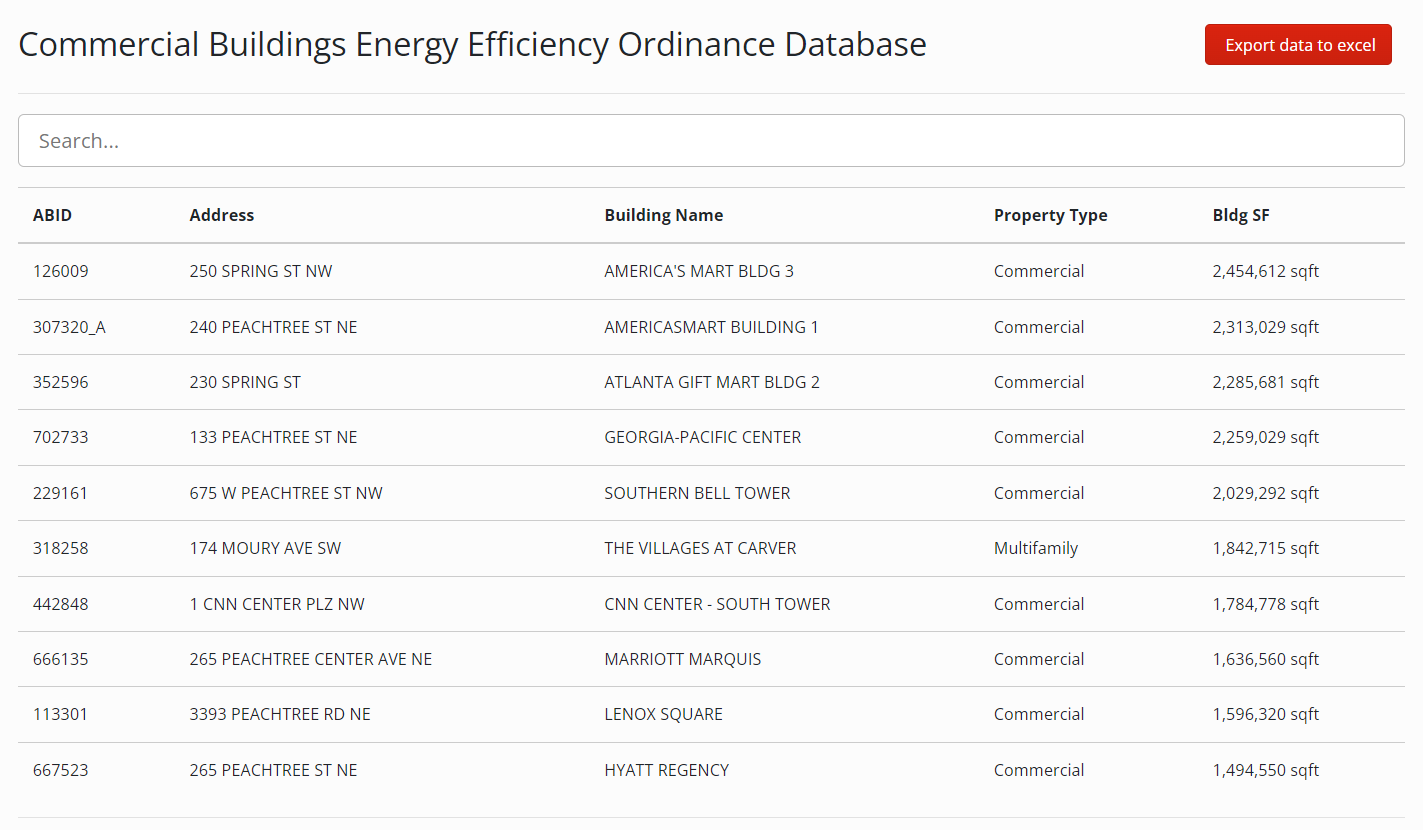

Rebates & Incentives – Many utilities offer financial incentives for high-efficiency HVAC upgrades

✔️

Better Indoor Air Quality – Improved filtration and ventilation

✔️

Less Downtime – Fewer emergency repairs and disruptions

✔️

Smart Controls & Automation – Modern units integrate with building automation systems for optimized performance

6. How Verdius Energy Can Help

At Verdius Energy, we specialize in helping building owners navigate HVAC replacement and retrofit decisions with a focus on lifecycle cost, sustainability, and occupant comfort. Our energy audits and compliance services ensure that your building operates efficiently while avoiding costly fines and unnecessary expenses.

Proactive planning for HVAC repairs and replacements helps reduce unexpected costs, improve building performance, and ensure compliance with local energy ordinances. If you’re unsure about your next step, Verdius Energy is here to guide you.

Would you like a consultation? Schedule a call with us today.