Carbon Leadership Forum's MEP 2040 Challenge

“All systems engineers shall advocate for and achieve net zero carbon in their projects: operational carbon by 2030 and embodied carbon by 2040.”

Carbon Leadership Forum (CLF) members are manufacturers, MEP firms and specialists who recognize the importance of reducing the impact of buildings on climate change. They want to work together to solve industry challenges and drive change.

Now they've launched their MEP 2040 Challenge: how can we reduce carbon emissions from heating, cooling and ventilation? This starts with operational carbon—the CO2 emitted by a facility as it operates each year—but involves embodied carbon from materials used in construction and other elements like transportation costs; net zero projects that offset all remaining emissions through green technology; and more efficient appliances.

Operational Carbon

Operational Carbon is the total amount of greenhouse gases associated with your business, across all activities and locations. The main sources of Operational Carbon are:

- emissions from energy use

- emissions from vehicle fleets (including employee travel)

- waste disposal and recycling activities

- refrigerants in air conditioning units

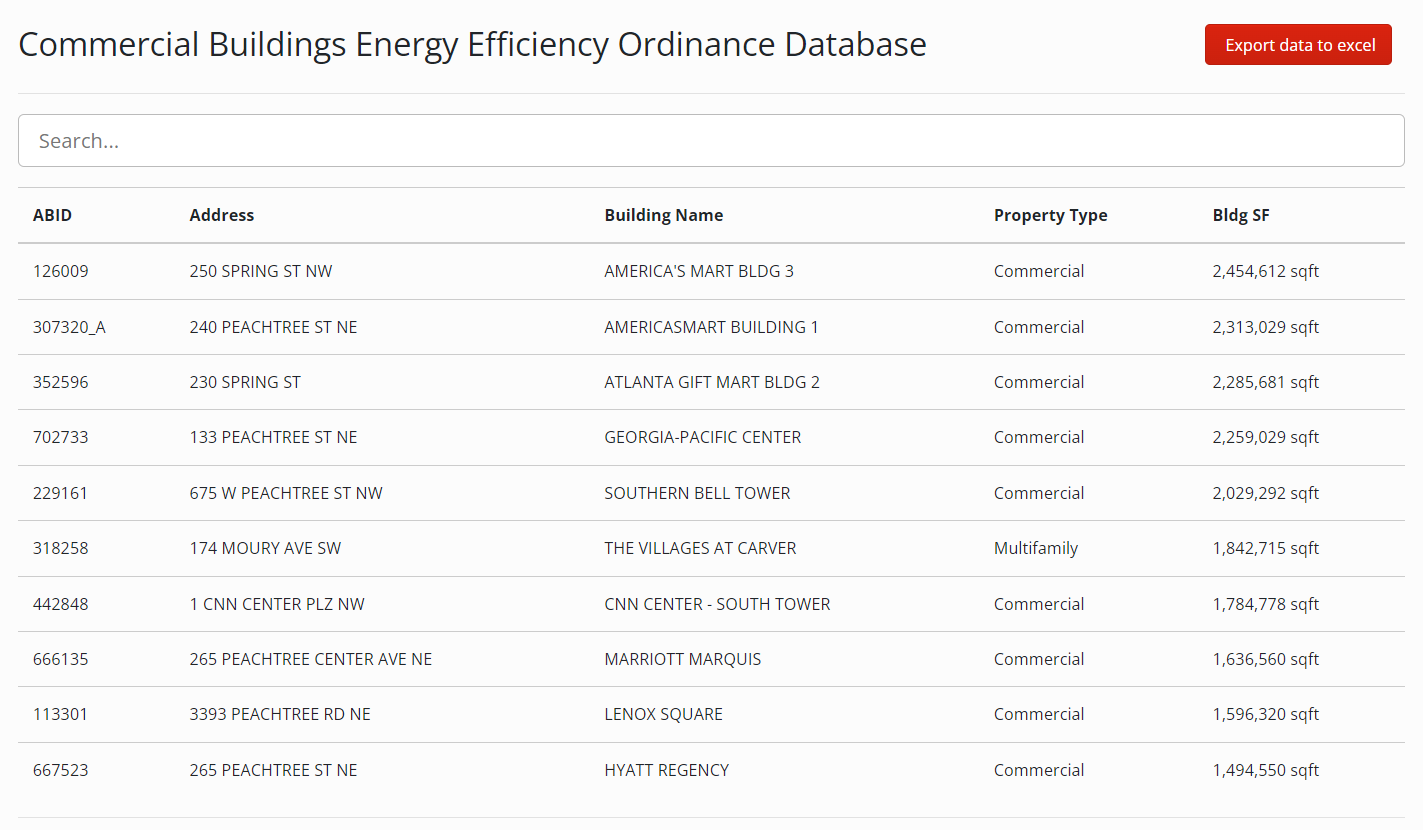

In order to measure your operational carbon footprint, you need to gather data on the following:

- how much energy you use in a year (kilowatt hours per month)

- where you get your electricity or gas from (if not generated on site)

- what types of fuel are used for heating/cooling systems

- how many vehicles are in use by employees or contractors on a monthly basis

- what percentage of waste is recycled onsite each month

Embodied Carbon

Embodied carbon is the carbon footprint of the materials and products that are used in a project. It's also known as indirect or embedded emissions, which means it includes all of the emissions associated with building a product or system—whether those emissions occur now or later (like when a solar panel breaks down).

Embodied carbon is important because it makes up almost half of an object's life cycle CO2 emissions. For example, if you're designing an office building, you need to account for all the embodied emissions related to constructing it, such as manufacturing and shipping concrete panels or windows from far away; buying furniture made from exotic wood shipped across oceans; or transporting employees who live beyond walking distance from work by automobile rather than public transportation. Because these factors all contribute significantly to greenhouse gas production over time (and therefore long-term climate change), they must be considered when creating sustainable buildings—especially since buildings often stay around for decades after their construction wraps up!

How can facilities engineers and property managers participate?

- Check with your HVAC and MEP contractors if they are MEP 2040 signatories

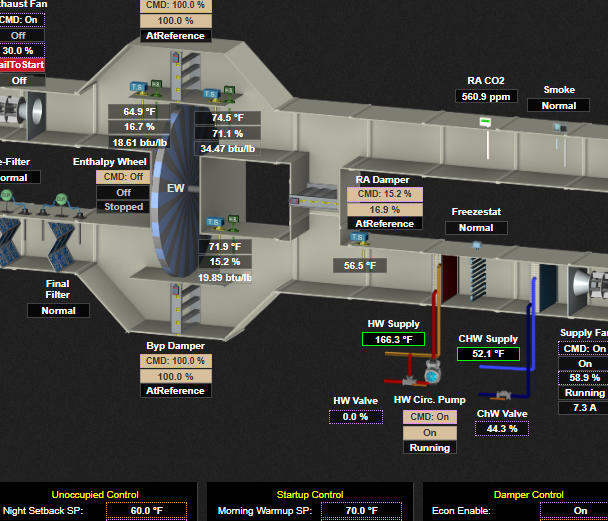

- Retro-commission your building HVAC systems

- Look into utility rebate programs for large equipment replacement

- Consider building electrification and renewable energy systems to eliminate onsite fossil fuel use

- Choose the most efficient lighting, heating, cooling and ventilation equipment

- Request Environmental Product Declarations (EPDs) in project specifications for MEP system components.

- Request HVAC installers and contractors use low-GWP refrigerant when replacing systems to reduce or eliminate GHG emissions from refrigerants.

- Verdius can help you with all of these -- don't hesitate to contact us!